Engineering Productivity Into Your Operations

From 40-second mold changes to zero-defect vision systems, Selplast integrates world-class manufacturing technologies that deliver measurable results in weeks, not years. Reduce injection molding changeover time, automate quality inspection, and optimize your factory floor with proven solutions.

Trusted Across Industries

From automotive giants to FMCG leaders, manufacturers rely on our solutions for critical production improvements

Complete Manufacturing Transformation

We integrate world-class technologies to slash changeover times, eliminate defects, and optimize your entire production floor.

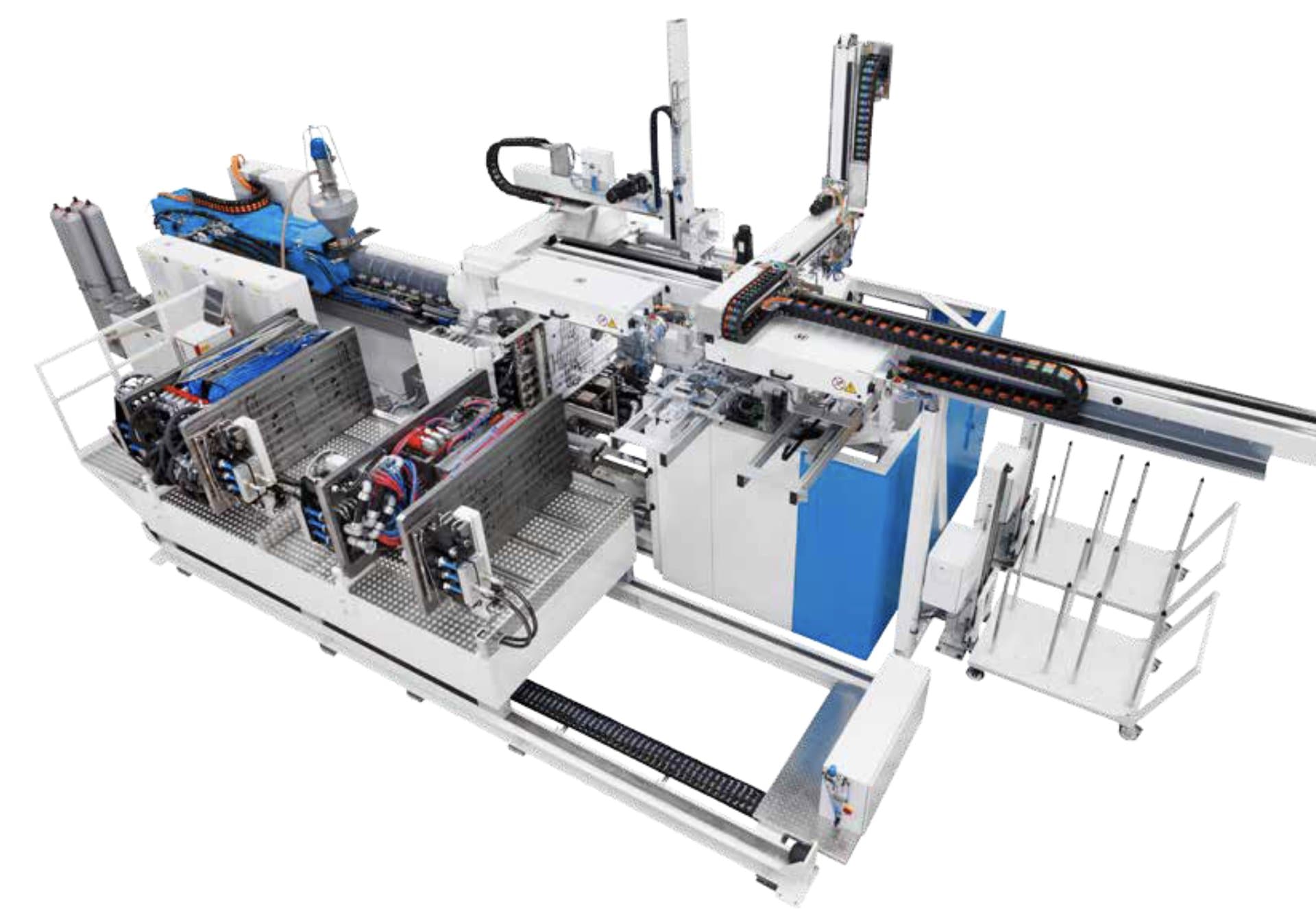

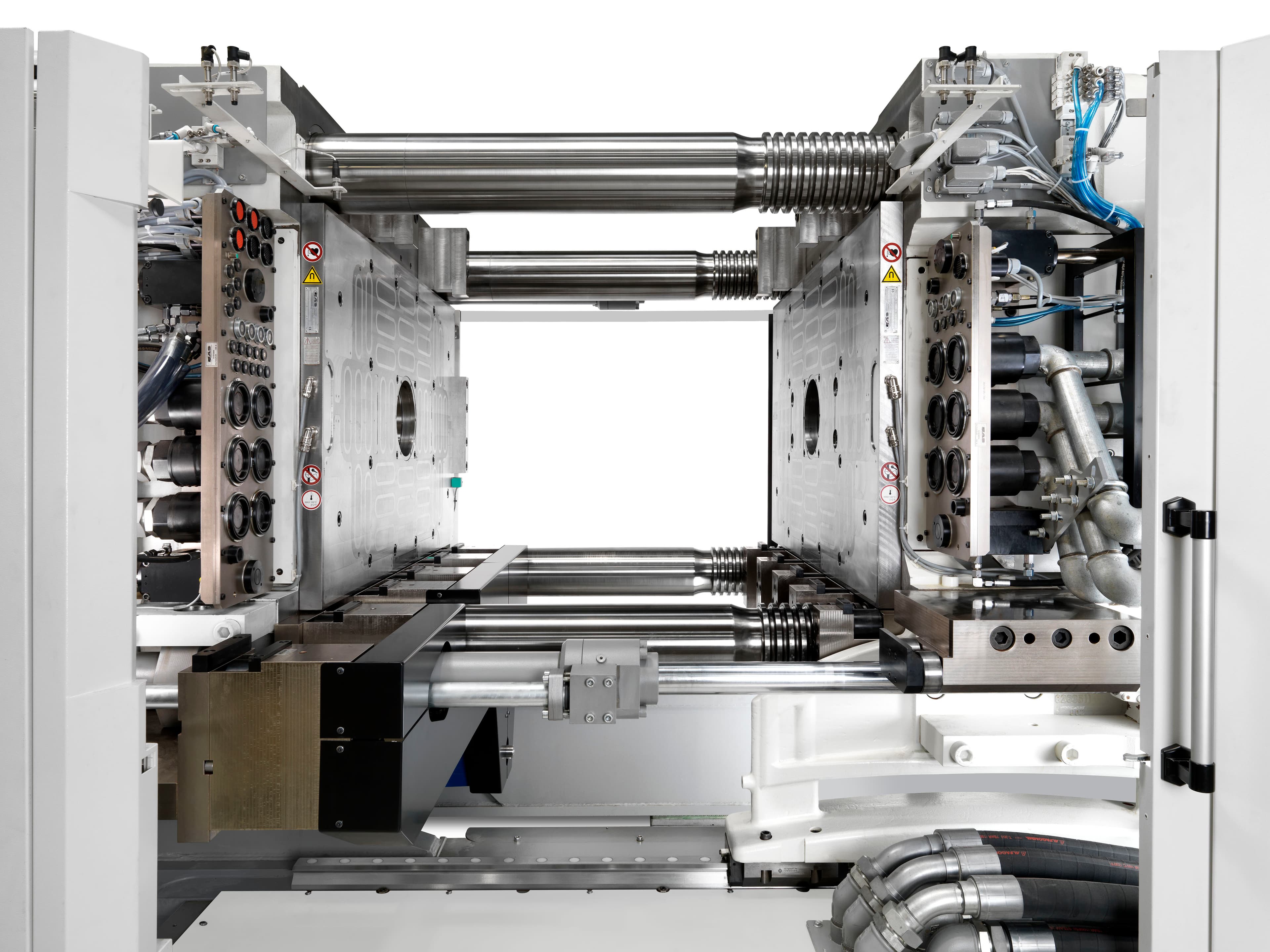

Cut 1-Hour Changeovers to 1-Minute Pit Stops

Complete SMED automation suite integrating magnetic/mechanical clamping, intelligent connection systems, and automated handling. We combine world-class technologies from European partners - from economical manual systems to fully automated cells achieving 47-second changeovers. Includes ultrasonic flow monitoring, multi-coupling plates, and smart lifting systems.

Explore SMED Solutions

Complete Automated Packaging Solutions

From bottle blow molding to final palletizing - complete turnkey packaging lines handling 1,000 to 40,000 bottles per hour. Integrated systems for filling, capping, labeling, case packing, and robotic palletizing. Reduce packaging labor costs while ensuring consistent quality and traceability.

View Packaging SolutionsCut Cycle Times by Up to 22%

Specialized hot runner insulation accelerates cooling, reduces energy consumption, and improves part quality—all with rapid payback.

Optimize Thermal Systems

Zero-Defect Vision Systems for High-Speed Production

AI-powered automated optical inspection for threaded components, precision parts, and assemblies. Detect surface defects, dimensional variations, and assembly errors at production speeds up to 600 parts per minute. Eliminate manual quality inspection while achieving 100% inspection coverage.

See Vision SystemsSpecialized Technologies

Critical solutions that complete your manufacturing transformation

Advanced Lubrication Systems

Extend equipment life by 3-5x with specialty greases engineered for extreme conditions. Reduce maintenance downtime significantly.

Learn More

Smart Factory Intelligence

Real-time production monitoring, predictive maintenance alerts, and actionable analytics. Turn your shop floor data into profit-driving decisions.

Learn MoreWhy Industry Leaders Choose Selplast

Proven at Scale

Installed on 25,000+ injection moulding machines worldwide. From automotive to FMCG, we've delivered solutions across every major manufacturing sector.

Technology That Works Here

We integrate best-in-class automation solutions from global technology leaders—carefully adapted for local conditions and operational requirements.

End-to-End Ownership

One partner from concept to commissioning. We handle integration complexity so you can focus on production, not vendor coordination.

Let's Discuss Your Production Challenges

Whether it's reducing changeover times, eliminating defects, or optimizing energy usage, we have proven solutions ready to deploy.