Complete SMED Automation Suite

We integrate world-class clamping, connection, and handling systems to slash your changeover times by 85%

Transform Your Changeovers from Hours to Minutes

4-8 hrs

Current State

47 sec

With SMED

Selplast's SMED/QMC automation offerings combines world-class technologies to revolutionize your changeover process:

- ✓Magnetic, hydraulic, or mechanical clamping systems

- ✓Quick-release couplings for all utilities

- ✓Automated lifting and transport systems

Real Achievement: 47-Second Changeover

Actual Installation Details

- Machine: 1300 Ton IMM

- Tool Weight: 15 Tons

- Changeover Time: 47 seconds

- Previous Time: 4-6 hours

This installation is currently operational in India, demonstrating the power of our integrated SMED solution:

- • EAS magnetic clamping for instant mould changes

- • RTC multi-couplers for all utilities

- • Automated handling systems

- • Integrated control systems

500+ Successful SMED Implementations Across India

From automotive giants to packaging leaders, we've helped Indian manufacturers achieve world-class changeover times

500+

Installations

20+

Years Experience

15+

Industries Served

Pan-India

Service Network

Complete SMED Solutions with World-Class Partners

From Assessment to Implementation

Downtime Analysis

We analyze your current changeover process and identify specific bottlenecks

Customized Solution Design

Select the right mix of technologies for your specific machines and moulds

Phased Implementation

Start with pilot machines, prove ROI, then scale across your facility

Training & Support

Comprehensive operator training and ongoing technical support

Our Implementation Process

Assessment

Design

Implement

Support

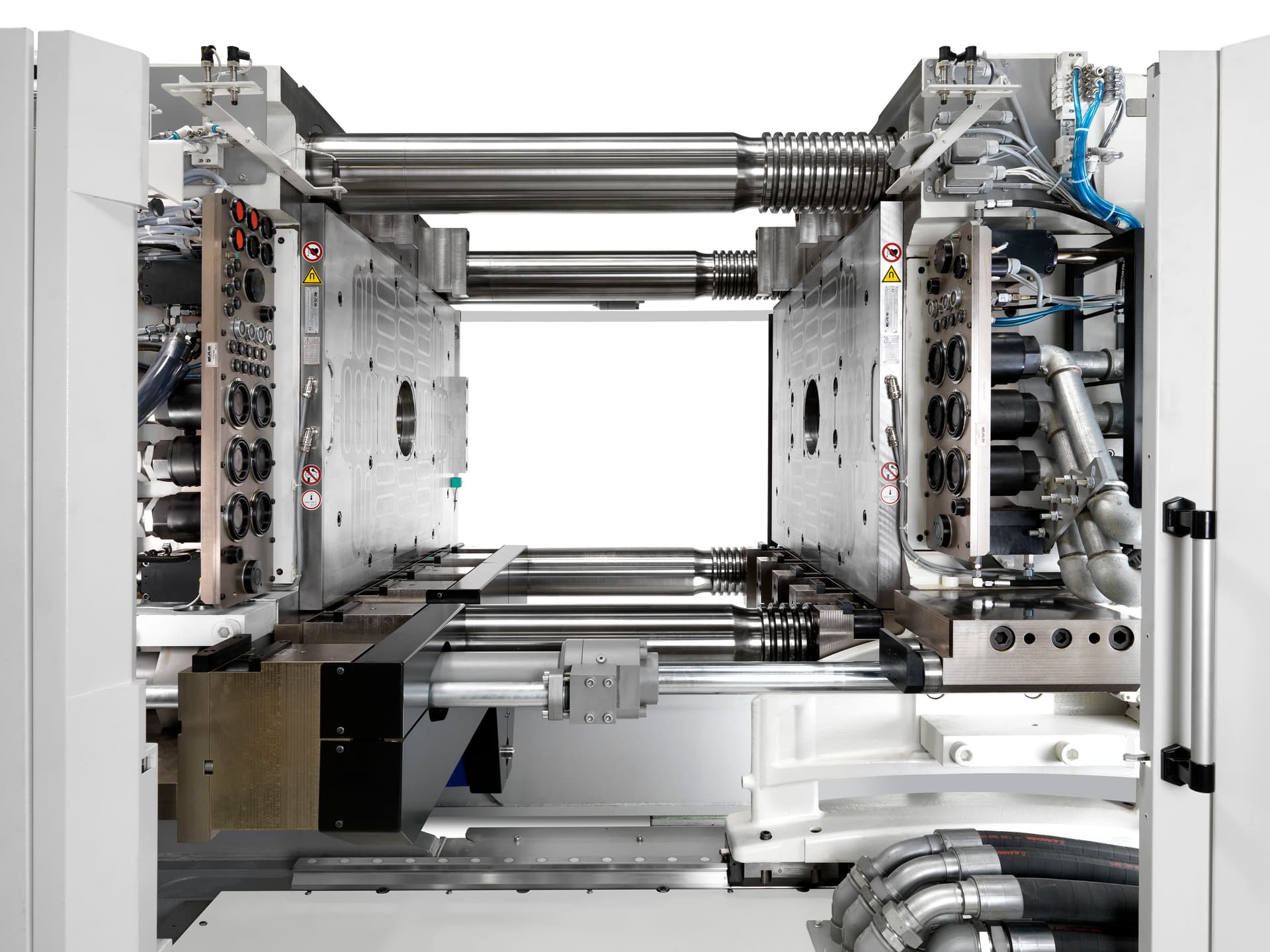

Complete SMED cell installation with EAS magnetic clamping, automated transport, and integrated controls

Why Selplast for SMED?

Expert SMED Implementation

Over 500 successful SMED implementations across Indian manufacturing since 1974

Solution-Focused Approach

We recommend the optimal technology mix for your specific requirements

Local Support

Pan-India service network ensuring rapid response and support

Complete SMED Technology Portfolio

Exclusive Technology Partners

Selplast is the sole Indian distributor for these world-class SMED technology leaders. We provide complete solutions by integrating their specialized products.

EAS Netherlands

Since 1974

Magnetic clamping, hydraulic systems, mould handling & complete automation

Lenzkes Germany

ISO 9001 & 14001

Patented mechanical clamping, 125,000+ installations worldwide

RTC Turkey

Coupling Experts

Quick-release couplings, multi-couplers, manifolds for all media

See how these technologies work together:

Advanced Clamping Systems

The foundation of any SMED system. Choose between magnetic, hydraulic, or mechanical clamping based on your frequency of changes and budget.

Showcasing select solutions from our extensive portfolio

EAS Magnetic Clamping Solutions

Pressmag LP system with integrated multi-couplers - complete SMED solution

50-400 ton presses

Thin magnetic plates that don't reduce your machine's daylight opening. Perfect for frequent mould changes on smaller presses.

- ✓Ultra-thin design (38mm)

- ✓Works with standard moulds

- ✓Heat-resistant options available

200-4500 ton presses

Powerful magnetic systems for heavy moulds. Touch-screen controls make operation simple even for massive tools.

- ✓Handles moulds up to 100 tons

- ✓Touch-screen operation

- ✓Force monitoring for safety

Key advantages

Unlike hydraulic clamps, magnetic systems need no power to hold. Your mould stays locked even during power failures.

- ✓Zero energy consumption when clamped

- ✓No hydraulic leaks or maintenance

- ✓Works with existing moulds

Lenzkes Mechanical Clamping Solutions

German-engineered mechanical clamping with unique stepless horizontal and vertical adjustability. Perfect for injection moulding, metal fabrication, manufacturing equipment, and pressure die casting.

Quick-Action Mechanical Clamps

How They Work

These mechanical clamps use a simple Allen key to lock moulds in place. The sliding arm design reaches over mould edges, and stepless adjustment means they work with any mould size.

- →3-7 minute total changeover time

- →No power or hydraulics needed

- →One operator can do the entire change

- →Works on machines from 50 to 5000 tons

Economical Frame-Style Clamps

Budget-Friendly Option

For companies starting their SMED journey, these frame-style clamps offer a cost-effective entry point. They're manually operated with a spanner but still cut changeover times dramatically.

- →5-10 minute changeover achievable

- →Adjusts to different mould heights (up to 260mm)

- →No modifications to moulds needed

- →Can be upgraded to quick-action later

Specialty Clamping Solutions

When your mould is too tall for standard clamps, these extension blocks bridge the gap. Available in aluminum or steel, they extend up to 1 meter high.

Chain clamps wrap around oddly-shaped moulds that regular clamps can't grip. Perfect for prototype moulds or non-standard tools.

When you can't access the mould from above, these side clamps grip from the machine's T-slots. Ideal for stack moulds or limited daylight.

Why Choose Lenzkes?

Forged alloy steel construction (not mild steel) ensures longevity and reliability

Used in plastics, metal fabrication, drilling, milling, stamping, and die casting

Lenzkes has 125,000+ installations worldwide achieving 30-60% downtime reduction

Additional hydraulic and pneumatic clamping solutions available - contact us for complete portfolio

Quick Connection Systems

Eliminate manual connection of water, oil, air, and electrical lines. Save 10-15 minutes per change while preventing costly leaks and accidents.

Featured solutions from our comprehensive coupling portfolio

RTC Quick Coupling Technology

M101 Multi-coupling manifold

Complete coupling range

Installed multi-coupling system

What Are Quick Couplings?

Think of the frustration when changing moulds - disconnecting and reconnecting dozens of water hoses, hydraulic lines, and air connections. Each connection risks leaks, takes time, and exposes operators to hot fluids. Quick couplings eliminate all of this.

Without Quick Couplings:

- • 10-15 minutes just for connections

- • Risk of cross-threading fittings

- • Fluid spills on floor (safety hazard)

- • Wrong connections damage moulds

With Quick Couplings:

- • Push-to-connect in seconds

- • No tools needed

- • Zero fluid loss design

- • Color-coded to prevent mistakes

For cooling channels. Non-drip design prevents water on the floor. Handles up to 16 bar pressure and 150°C temperature.

For core pulls and slides. Connect under full pressure - no need to depressurize. Rated up to 550 bar.

For mould venting and air ejectors. Safety venting prevents dangerous whip if disconnected under pressure.

Mechanical ejector connections that engage automatically when mould closes. No manual connection needed.

For special applications including hot oil up to 325°C. Compatible with various seal materials for different chemical media.

Multi-Coupling Plates: Connect Everything in One Push

Connect Everything at Once

Instead of connecting 20 individual lines, imagine connecting everything with one simple push. Multi-coupling plates mount all your connections in a single unit:

- →All water cooling circuits

- →Hydraulic core pulls

- →Air circuits

- →Even electrical connections

Real impact: What took 15 minutes now takes 30 seconds. One operator can handle moulds that previously needed two people.

How Multi-Plates Work

- 1. Fixed plate stays on machine

- 2. Moving plate mounted on mould

- 3. Guide pins ensure perfect alignment

- 4. One push connects everything

- 5. Color coding prevents wrong moulds

Available from 4 to 24 connections per plate

Advanced Cooling Circuit Monitoring

Ultrasonic Flow Control System

RTC's ultrasonic flow monitoring provides contactless measurement of cooling circuit performance. Unlike mechanical flow meters, ultrasonic sensors eliminate pressure drops and contamination risks while delivering real-time data on flow rates, temperature, and pressure.

Key benefit: Detect cooling anomalies immediately - partial blockages, flow imbalances, or temperature deviations - preventing part defects and reducing scrap rates.

Intelligent Mould Handling Systems

The most dangerous part of mould changes. Our solutions eliminate manual lifting, reduce operator fatigue, and prevent costly accidents.

Selected handling and automation solutions from our partners

EAS Mould Shop Automation

Complete automated cell with magnetic clamping, transport, and storage

Multi-tier automated mould storage with retrieval system

Moving moulds safely

Battery-powered carts that move moulds between storage and machine. Some even float on air cushions for effortless movement of heavy tools.

Handles: Up to 40 tons

Find moulds instantly

Multi-tier racks with RFID tracking mean no more hunting for moulds. Climate control prevents rust on expensive tools.

Result: 60% less space needed

Complete automation

Mould rotators for inspection, pre-heating stations to avoid condensation, and side-loaders for machines with limited access.

Ready for: Industry 4.0

Proven Results from Indian Manufacturers

Don't just take our word for it. See how leading Indian companies have transformed their operations with our SMED solutions.

Chennai, Tamil Nadu

4 hrs → 12 min

Changeover time reduction

95% Reduction

Setup time saved

Solution: EAS magnetic clamping + RTC manifolds on 850T machines

ROI achieved in 8 months

Haridwar, Uttarakhand

6 hrs → 45 min

Changeover time reduction

87% Reduction

Downtime eliminated

Solution: Lenzkes mechanical QMC system on 450T machines

₹1.2 Cr annual savings

Daman, Daman & Diu

3 hrs → 8 min

Changeover time reduction

96% Reduction

Setup efficiency gain

Solution: Full EAS automation suite with auto-connect on 250T machines

35% increase in capacity

Average Results Across 500+ Implementations

85%

Reduction in Changeover Time

40%

Increase in Machine Utilization

12 Months

Average Payback Period

Zero

Accidents After Implementation

Transform Your Manufacturing with SMED

- Reduce Changeover Times by 85%: From hours to minutes

- Improve Safety: Eliminate manual handling injuries

- Increase Flexibility: Accept smaller, more profitable orders

- Boost OEE: Add 2-3 hours of production time per day

- Enable JIT Production: Respond faster to market demands

Download Resources & Watch Videos

See SMED in Action

Complete Process Videos

Equipment Demos

Advanced Solutions

Technical Documentation

Complete SMED solutions catalog from Selplast

Download PDF →Magnetic clamping & automation systems

Download PDF →Mechanical quick clamps catalog

Download PDF →Quick release coupling systems

Download PDF →Your Path to World-Class Manufacturing

Why Companies Choose Selplast for SMED

We Understand Your Reality

Your operators are skilled. Your processes work. We don't replace - we enhance. Our solutions work with your existing moulds and methods.

Proven Technology, Local Support

World-class technology from Europe backed by engineers who understand Indian manufacturing. Support in your language, in your time zone.

Start Small, Scale Fast

Begin with one machine. Prove the ROI. Then expand. Many clients start with mechanical clamps and upgrade to magnetic later.

Real Results, Not Theory

500+ installations across India. From Haridwar to Chennai. From 50-ton to 4500-ton machines. We've done it all.

The question isn't whether SMED will transform your operations.

The question is: Can you afford to wait while your competitors implement it first?

47

Seconds Achieved

4-8

Hours Typical